The Role of Industrial Scales in Quality Control and Assurance

The Role of Industrial Scales in Quality Control and Assurance

Blog Article

Why Industrial Scales Are Vital for Maximizing Stockroom Workflow

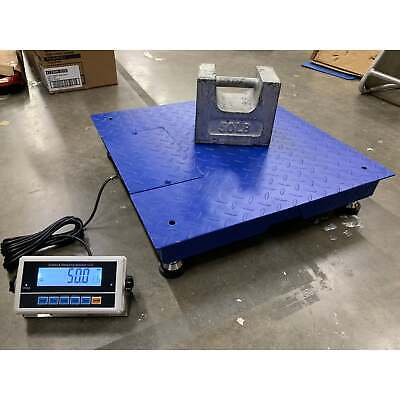

Industrial ranges play an essential function in maximizing storage facility procedures by delivering specific weight dimensions that are crucial for efficient supply management and streamlined shipping processes. Their capability to guarantee precision not only reduces problems of overstocking and stockouts but additionally contributes substantially to lose decrease and price performance. The information produced from these scales permits for educated decision-making, boosting source allocation and functional performance. Nonetheless, the true influence of commercial scales extends past mere precision-- understanding their wider implications could transform functional strategies in unforeseen methods.

Boosted Precision in Considering

In lots of storehouse operations, achieving enhanced precision in weighing is essential for the general efficiency and dependability of supply administration. Precise weighing enables precise monitoring of item quantities, which is vital for preserving ideal stock degrees and decreasing waste. Industrial ranges developed for warehouse environments offer high degrees of accuracy, therefore reducing the margin for mistake in inventory evaluations.

Executing innovative considering technology, such as digital ranges with calibration features, ensures that weights are consistently precise across numerous lots. This precision is specifically essential when dealing with bulk materials or high-value items, as inconsistencies can bring about significant financial losses. Furthermore, exact considering adds to conformity with market laws, which typically mandate exact measurement for safety and top quality guarantee.

Additionally, improved weighing precision allows better decision-making regarding logistics and supply chain management. With specific data at hand, stockroom managers can anticipate need better, prepare for replenishment, and optimize storage space usage. Ultimately, the assimilation of precise commercial scales right into storage facility operations supports not just prompt functional requirements but likewise lasting critical objectives targeted at improving general productivity and earnings.

Enhanced Supply Monitoring

Effective inventory management is necessary for enhancing storage facility procedures and making certain that sources are utilized effectively. Industrial scales play a critical duty in this procedure by supplying exact weight measurements that directly affect inventory monitoring and control. By incorporating these scales right into inventory administration systems, storehouses can attain real-time data accuracy, which is critical for keeping optimal stock degrees.

The capacity to weigh items properly permits far better projecting and replenishment approaches. With exact weight information, storehouse managers can determine inconsistencies between anticipated and real supply degrees, consequently reducing overstocking or stockouts. This accuracy additionally aids in categorizing products according to weight, which can boost storage space performance and improve order choosing procedures.

Additionally, enhanced inventory management fosters much better provider relationships and consumer satisfaction. Exact weight measurements promote conformity with shipping guidelines and decrease the chance of expensive errors during the procurement procedure. Essentially, commercial scales not just boost the accuracy of inventory records yet additionally contribute to overall operational performance, ultimately leading to lowered costs and boosted service shipment in storage facility operations.

Streamlined Shipping Processes

A significant aspect of storehouse efficiency is the streamlining of shipping procedures, Learn More Here which can greatly improve general performance and client satisfaction. Reliable delivery operations ensure that products are dispatched accurately and in a timely way, straight impacting customer experience and retention.

Moreover, incorporating industrial ranges right into stockroom management systems helps with real-time tracking of supply and shipments, improving transparency throughout the delivery process - Industrial Scales. This combination not only speeds up the satisfaction cycle yet additionally improves communication among staff, bring about quicker decision-making and less bottlenecks

In addition, structured shipping procedures can lower labor costs, as groups can work a lot more effectively with clear standards and accurate information at their fingertips. By adopting commercial ranges, warehouses can achieve an extra organized approach to delivery, eventually increasing their functional efficiency and supporting a stronger profits.

Waste Decrease Techniques

Enhancing warehouse procedures prolongs beyond streamlined shipping procedures to incorporate waste reduction approaches that considerably contribute to general efficiency and cost-effectiveness (Industrial Scales). Applying industrial scales is a crucial aspect of these methods, making it possible for accurate dimension of products and products, which lessens excess and decreases excess inventory

Another vital method is the optimization of packaging. Industrial scales help with precise weight dimensions, allowing for customized packaging services that my latest blog post decrease excess products. This not just minimizes waste however also lowers shipping costs, as lighter bundles often incur reduced freight fees.

Data-Driven Choice Making

Utilizing information created from commercial ranges enables warehouse supervisors to track supply levels extra accurately, bring about informed investing in decisions and reducing overstock or stockouts. Furthermore, this data can be assessed to identify patterns in item motion, allowing better forecasting and resource allowance.

The understandings got why not look here from weight data likewise facilitate performance measurement versus essential efficiency indicators (KPIs), such as throughput prices and order precision. By employing innovative analytics, stockroom procedures can uncover ineffectiveness, improve workflows, and minimize operational costs.

Eventually, data-driven choice making equips organizations to make positive modifications, ensuring that storehouse operations continue to be nimble and receptive to market demands. Buying industrial scales not only boosts information collection yet likewise changes that information into actionable intelligence, positioning stockrooms for sustained competition and development.

Final Thought

In recap, commercial ranges play a crucial role in enhancing stockroom procedures with enhanced precision in weighing, boosted stock administration, and structured shipping procedures. The assimilation of commercial ranges into storage facility management systems is hence extremely important for accomplishing ideal performance and resource allotment.

Industrial ranges play an essential duty in enhancing storage facility procedures by delivering precise weight measurements that are crucial for efficient inventory management and structured delivery procedures. Industrial scales developed for stockroom environments give high degrees of accuracy, thus reducing the margin for mistake in inventory assessments.

In significance, industrial scales not just improve the precision of inventory documents but likewise contribute to general functional effectiveness, ultimately leading to minimized prices and boosted service distribution in warehouse operations.

In recap, industrial scales play a critical duty in optimizing warehouse procedures through enhanced accuracy in considering, enhanced supply monitoring, and structured delivery processes. The assimilation of industrial scales into stockroom management systems is hence paramount for accomplishing optimal efficiency and resource allotment.

Report this page